Aluminium 106 4 Seater Dining Set

£999.00

This Set Includes:

4x Fire and Ice Dining Chair

4x Harvest Cushions

1x 106cm Table

Our Aluminium 106 4 Seater Dining Set includes a 106cm round dining table with four fire and ice dining chairs perfect for alfresco dining.

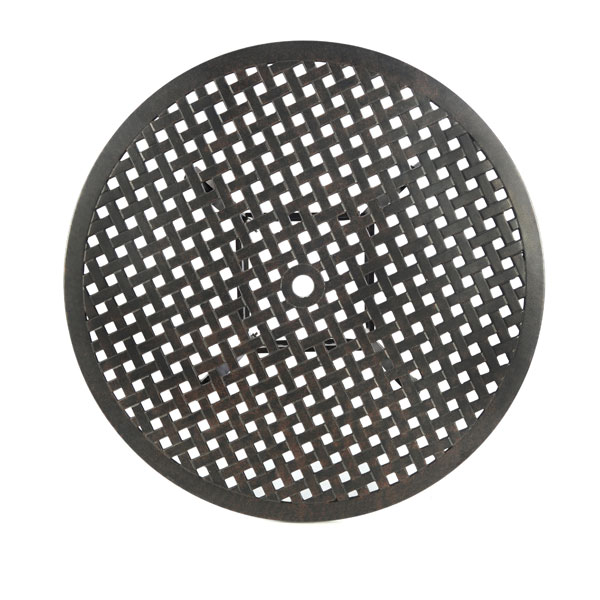

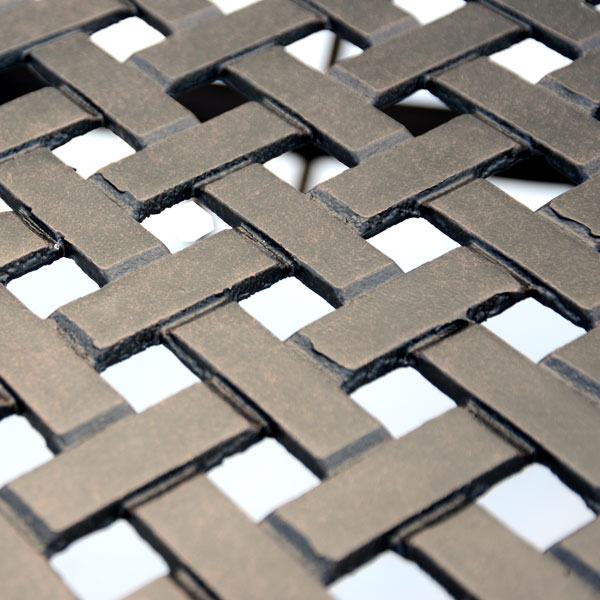

This metal dining set has been to last! Our 106cm Tables have cast aluminium lattice table tops which attach to the leg section easily. Our 106 tables have been powered coated using high quality product.

The Fire and Ice Dining Armchairs have removal cushion covers which can be machine washed on a 30' wash. These metal dining chairs can be stacked in heights of six. Each Chair weighs 9kg therefore easy to move around your outside space.

Powder Coating & Aluminium - Our high quality powder coating means that this metal garden set can be left outside for several years before re-painting has to be considered. Aluminium does not rust like cast iron, so our garden furniture is totally maintenance free, Wash with soapy water and a hose.

The price for this metal garden set includes: 1 x Round Ø 106cm metal table in antique bronze. 4 x Aluminium garden Fire and Ice dining chairs (delivered assembled) 4 x Harvest colour cushions.

Aluminium 106 4 Seater Dining Set - Technical Specifications -

4 x Dining Chairs = Width 65cm | Height 94 | Depth 61cm | Weight 9kg

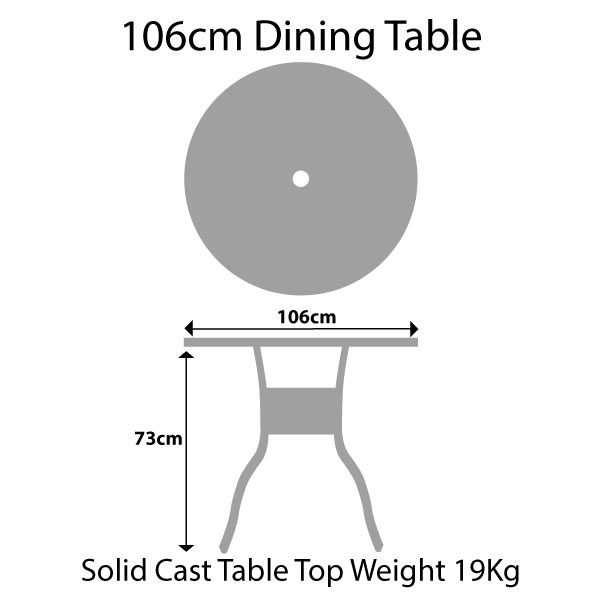

Table Diameter = Diameter 106cm Round | Height 73cm | Weight 19kg

Guarantee - This set has a 10 year structural warranty, for more information view our Terms and Conditions.

Additional information

| Assembly Required | Table Only |

|---|---|

| Cushion Colour | Harvest |

| Frame | Cast Aluminium |

| Frame Colour | Antique Bronze |

| Seats | 4 |

| Table Option | Round Dining Height |